Customer

Alcoa Norway AS, Mosjøen (Norway)

Task & Solution

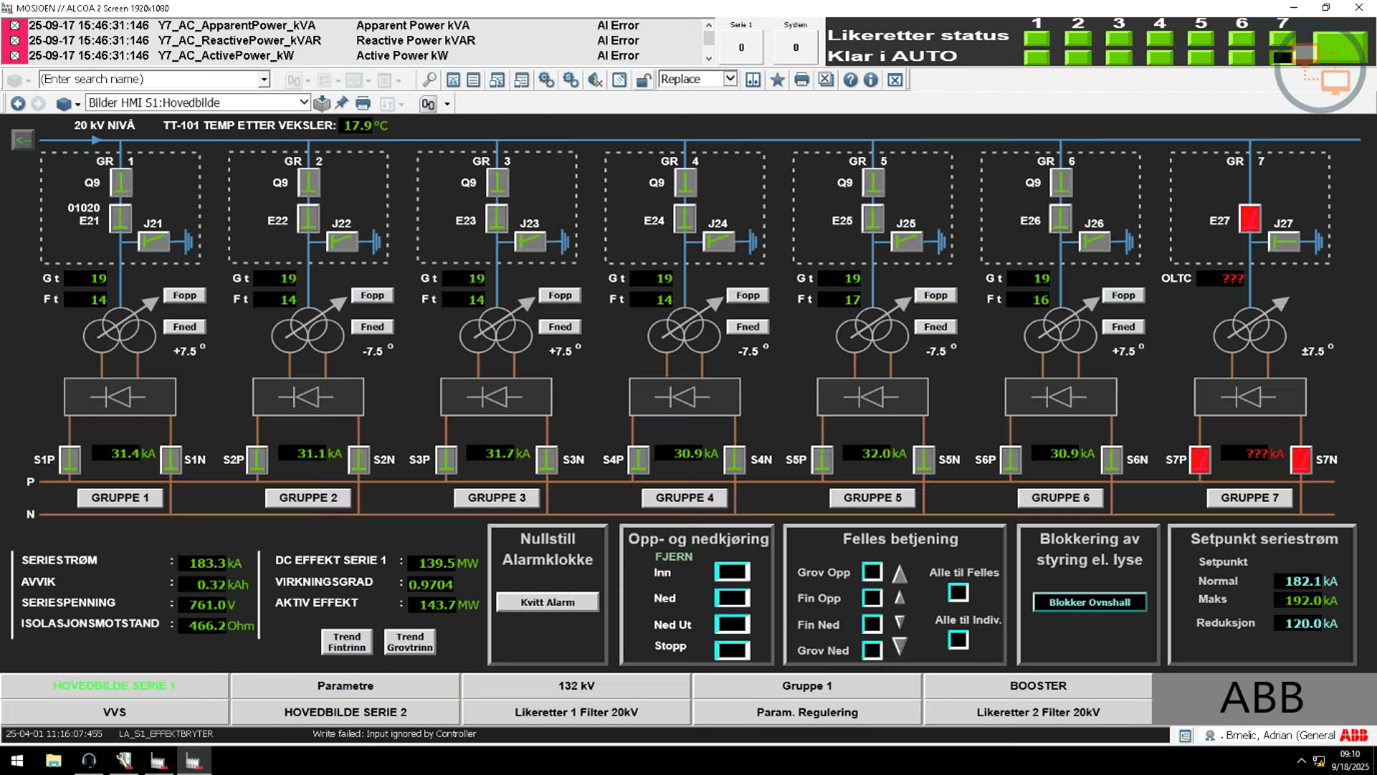

Alcoa’s aluminum plant in Norway continues to enhance its production capabilities with the addition of Rectifier 7 to the existing six rectifiers. Unlike the previous units, Rectifier 7 is supplied by FRIEM, which comparing to the previous ones has a higher capacity. This brings its own challenges regarding integration and functionality.

The integration was implemented using ABB’s 800xA system with Control Builder and Functional Designer as it was the previous standard in the plant.

The setup provides operators with real-time insight into rectifier status, operational parameters, and performance metrics, ensuring smooth operation and rapid response to any anomalies.

The system supports centralized supervision while allowing detailed, per-unit monitoring, enabling the client to optimize production efficiency, minimize downtime, and maintain the highest standards of safety and operational control.