The drying section of a paper machine plays a crucial role in removing the remaining moisture from the paper web after it leaves the press section.

This process is primarily achieved through the use of steam-heated drying cylinders, which transfer heat to the paper and evaporate water efficiently.

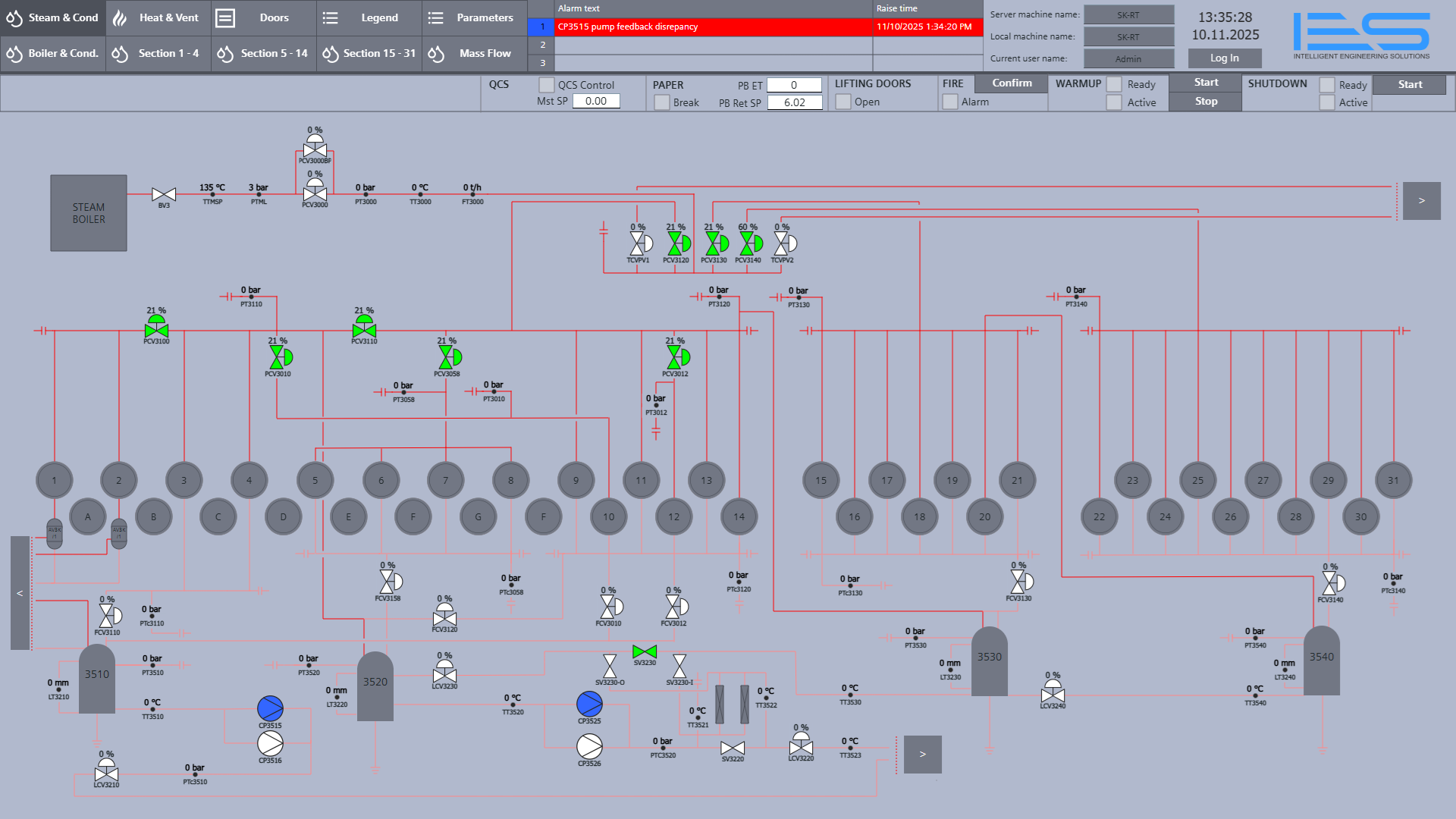

The steam and condensate system ensures optimal heat transfer by maintaining stable pressure, temperature, and condensate removal across the dryer groups.

In parallel, the hood and ventilation system controls the drying air temperature, humidity, and exhaust, enhancing energy efficiency and

providing a stable drying environment. Together, these systems work in harmony to achieve consistent paper quality,

reduce energy consumption, and ensure safe and reliable operation of the machine.

Customer

SAM Progetti SA, Lugano (Switzerland), Buchurest (Romania)

Task

The task was implementing from scratch a drying section module of a paper machine. Task included creation of electrical schematics, assembeling of 2 separate electrical cabinets for

different parts of drying section module, process logic software development and SCADA design and integration with PLC.

Solution

As part of this project, our team developed and implemented the complete PLC process logic and SCADA visualization system for the drying section. We also designed detailed electrical schematics for two separate electrical cabinets and assembled and tested the cabinets in-house before commissioning. The result is a fully automated and user-friendly control system that enhances operational reliability, provides real-time monitoring and diagnostics, and allows efficient process control for the customer’s paper production line.

Hardware

Electrical cabinets, Siemens S7-1500 PLC, WinCC Unifed SCADA system

Software

EPLAN, Siemens TIA Portal, WinCC Unifed